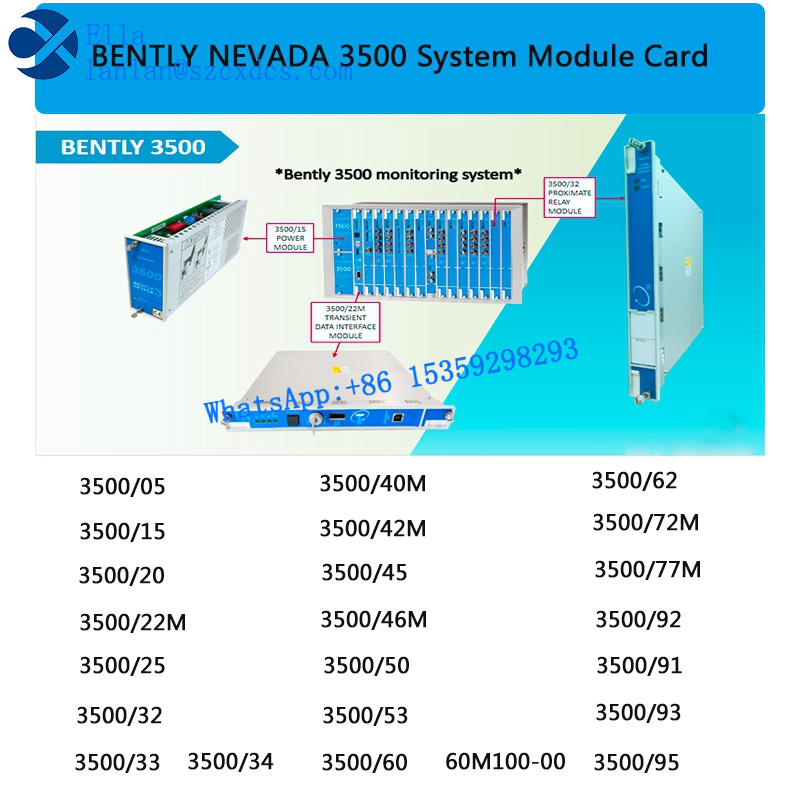

BENTLY 3500 is an industrial grade mechanical protection and condition monitoring system launched by Bently Nevada, designed specifically for industrial equipment with high reliability requirements, covering core areas such as power, petrochemicals, metallurgy, and ships.

Function:

Real time monitoring: high-precision acquisition and analysis of key parameters such as vibration, displacement, temperature, and speed;

Fault warning: Implement equipment health management through threshold alarms and trend analysis to reduce the risk of unplanned downtime;

Redundant Fault Tolerance: Supports Triple Modular Redundancy (TMR) design to ensure system reliability under extreme operating conditions.

| Module type: | Function description |

| Framework (3500/05): | Main control unit, integrated backplane communication and power distribution, supports modular expansion |

| Power module (3500/15): | Dual power redundancy design, supports hot swapping, ensures continuous system operation |

| Interface module (3500/20): | data communication hub, supporting interconnection with upper computer, DCS/PLC system |

| Monitor module (3500/42M): | Diversified signal processing unit (such as vibration, temperature, and speed monitoring) |

| Relay module (3500/32): | Output control signal, trigger shutdown protection or alarm prompt |

Typical Case Analysis

Case 1: Steam Turbine Protection System in Thermal Power Plant

Requirement background: A 1000MW supercritical unit needs to improve the accuracy of turbine vibration monitoring and reduce unplanned shutdown rate.

Solution:

Deploy 3500/42M vibration monitoring module, with a sampling frequency of 10kHz and an accuracy of ± 0.5% FS;

Configure 3500/34 triple redundant relays to ensure zero misoperation of emergency stop signals.

Implementation effect:

Reduce annual downtime by 80% and maintenance costs by 35%;

Integrating SECS/GEM protocol with power plant MES system to achieve predictive maintenance .

Case 2: Monitoring of Centrifugal Compressors in Petrochemical Industry

Background of the demand: A certain refining and chemical enterprise needs to solve the sealing leakage problem caused by excessive displacement of the compressor shaft.

Solution:

Adopting a 3500/40M displacement monitoring module, with a range of ± 5mm and a resolution of 0.1 μ m4;

Linkage 3500/32 relay module triggers interlock shutdown protection .

Implementation effect:

The response time for axis displacement exceeding the standard event has been shortened to 20ms, avoiding single accident losses exceeding 2 million yuan;

The mean time between failures (MTBF) of the equipment has been increased to 30000 hours.

BENTLY 3500 series mainstream models and parameters

| Model | functional | characteristics, key parameters |

| 3500/40M | displacement monitoring module range | ± 5mm; resolution: 0.1 μ m; Input signal: Eddy current sensor (8-24V DC) 46 |

| 3500/92 | three in one monitoring module | frequency range: 0.5Hz-10kHz; Accuracy: ± 0.5% FS; supports ISO 10816 standard alarm 46 |

| 3500/45 | Differential Expansion and Axial Position Monitoring Module | Range: ± 25mm; Linearity: ± 1%; Working temperature: -40 ℃ -85 ℃ 4 |

| 3500/50M | speed monitoring module | measurement range: 0-30000 RPM; Accuracy: ± 0.01%; Supports Keyphasor Input (TTL/HTL) 46 |

| 3500/53 | electronic overspeed detection system | response time: ≤ 2ms; redundant design: dual channel voting; Output contact capacity: 5A @ 250V AC46 |

View more…

Bently Newada 3500/22-01-01-00

Bently Newada 3500/15-02-00-00

Bently Newada 133396-01 3500/53-03-03-00 133388-01 133396-01

Bently Newada 125720-01 3500/32-01-00 125712-01 125720-01

Bently Newada 128229-01 3500/42M-01-00 176449-02 128229-01

Bently Newada 126648-01

Bently Newada 138708-01

Bently Newada 133323-01

Bently Newada 3500/25 125800-01

Bently Newada 125768-01

Bently Newada 125760-01

Bently Newada 125680-01

3500/40-01-00 176449-01 125680-01